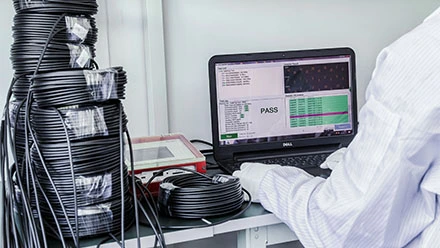

We are committed to providing our customers with high-quality products. To ensure our products meet industrial standards, we implement stringent monitoring measures throughout the entire production and quality control process, guaranteeing exceptional quality for every product.

ISO management, document maintenance, internal audits, quality KPI reporting, and calibration management.

Supply Chain Management, New Material Approval, Incoming Quality Control, Material Review Committee.

Process Quality Control, ESD Management, Quality Improvement Team.

New Product Introduction, Return Merchandise Authorization, Customer Audits, Outgoing Quality Control.

After-sales service covers technical support, troubleshooting and solution provision. If you encounter problems while using the product, you can get professional guidance and assistance through phone, email or online customer service to ensure customer satisfaction and continued efficient use of the product.

Each cable is subjected to rigorous extreme environment stress tests, including high-temperature and high-humidity testing, as well as high-to-low-temperature cycle testing.

HDMI fiber optic cables are designed to withstand over 450kgf of compression, as proven through rigorous crush resistance testing. This ensures exceptional durability and reliability in every cable.

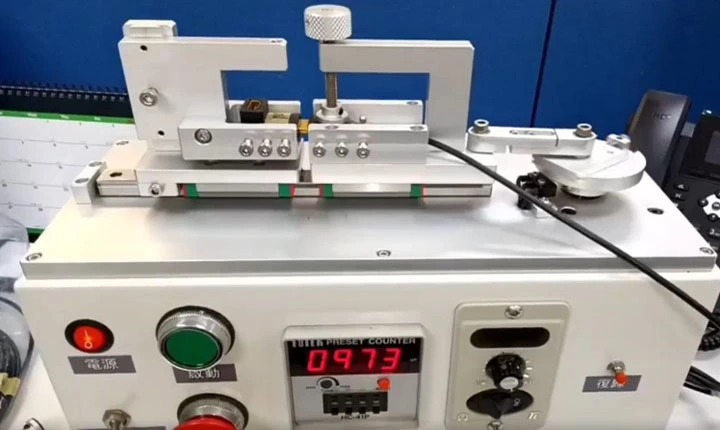

AOCFiberLink rigorously tests all cables with repeated plug-and-unplug cycles to guarantee the durability of at least 10,000 connections and disconnections during regular use.

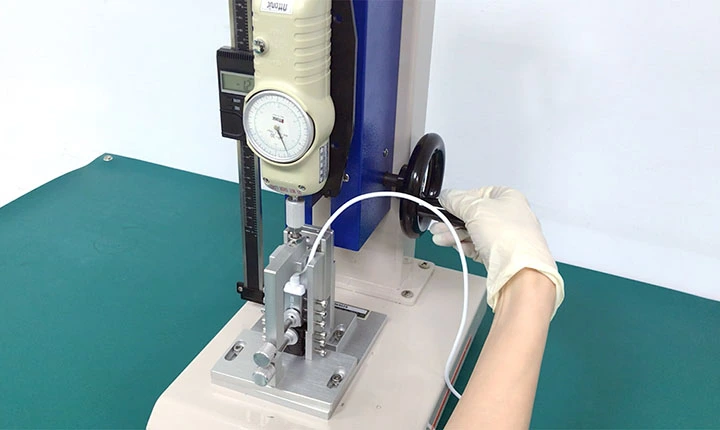

Conducts Wrenching Strength Tests to ensure the cables can endure the forces experienced during regular use and accidental pulls. Ensure every each cable meets the highest standard.

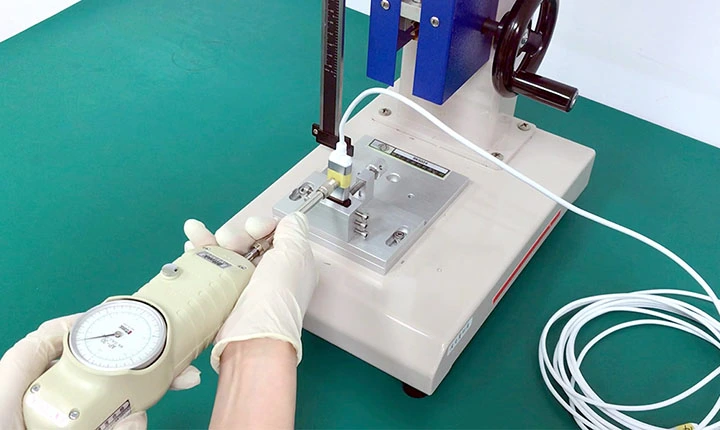

Conducts Insertion and Extraction Force Test to simulate the forces exerted during cable insertion and removal, ensuring the durability and reliability of both the cable housing and connectors.

Ensures the production of high-quality cables capable of resisting pull-out damage. Every cable undergoes a specially designed in-house pull-out test before entering mass production.